Summary:When installing or replacing PU timing belts, it's crucial to prioritize safety to prevent injuries and ensure proper functioning of the equipment. Here are some key safety precautions to consider:Wear appropriate personal protective equipment (PPE):......

When installing or replacing PU timing belts, it's crucial to prioritize safety to prevent injuries and ensure proper functioning of the equipment. Here are some key safety precautions to consider:

Wear appropriate personal protective equipment (PPE): Personal protective equipment serves as the first line of defense against potential hazards encountered during PU timing belt installation or replacement. Safety glasses with side shields protect the eyes from flying debris or particles, while gloves provide hand protection against sharp edges, abrasions, and chemical exposure. Wearing appropriate clothing, such as long sleeves and pants, further reduces the risk of injury from mechanical or chemical sources.

Ensure equipment is powered off: Before initiating any maintenance activities, it is imperative to ensure that the machinery or equipment associated with the PU timing belt is completely powered off. This entails shutting down all power sources, including electrical, hydraulic, or pneumatic systems, and locking out energy isolation devices to prevent accidental startup. Verifying that the equipment is de-energized minimizes the risk of electrical shocks, mechanical entanglement, or other serious accidents during installation or replacement procedures.

Lockout/tagout procedures: Lockout/tagout (LOTO) procedures provide a systematic approach to controlling hazardous energy sources and safeguarding personnel from unexpected equipment activation. Following LOTO protocols involves applying locks and tags to energy isolation devices, such as circuit breakers or valves, to prevent their operation. Additionally, conducting a thorough verification process ensures that all energy sources have been effectively isolated before commencing work on the PU timing belt, thereby enhancing worker safety and compliance with regulatory requirements.

Use proper tools: Utilizing the appropriate tools recommended by the manufacturer is essential for ensuring safe and efficient installation or replacement of PU timing belts. These tools may include wrenches, socket sets, belt tension gauges, and alignment tools specifically designed for the task at hand. By using the correct tools for each step of the process, users minimize the risk of damage to components, achieve precise adjustments, and maintain compliance with manufacturer specifications.

Inspect components: Prior to installation or replacement, conducting a comprehensive inspection of all timing belt system components is paramount. This involves visually examining pulleys, tensioners, bearings, and other related parts for signs of wear, corrosion, or damage. Verifying proper alignment and functionality of these components ensures optimal performance and longevity of the PU timing belt. Any identified issues should be promptly addressed through repair or replacement using genuine manufacturer-approved parts to maintain system integrity and reliability.

Handle with care: Proper handling of the PU timing belt is crucial to prevent damage that could compromise its performance and longevity. When transporting or maneuvering the belt, avoid excessive bending, twisting, or folding beyond its specified minimum bend radius. Care should also be taken to prevent exposure to sharp objects, abrasive surfaces, or contaminants that may cause abrasion or degradation of the belt material. By exercising caution and handling the belt with care, users can preserve its integrity and ensure consistent performance over its service life.

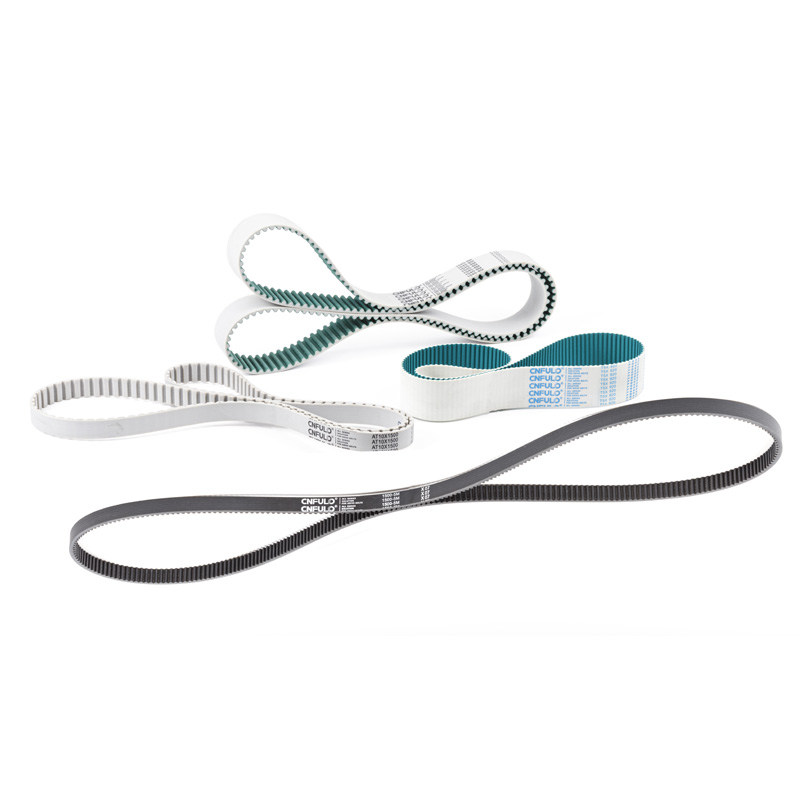

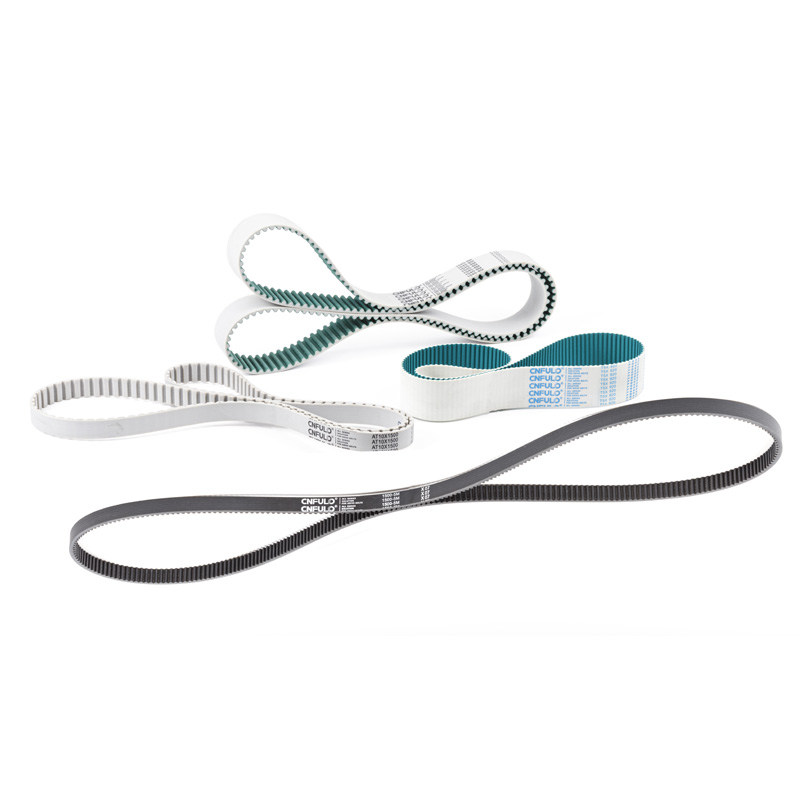

PU Welded Timing Belt