Summary:The industrial synchronous belt, also known as a timing belt, is a crucial component in modern manufacturing processes. It plays a vital role in transmitting power and synchronizing the movement of various machinery and equipment. This essay aims to ......

The

industrial synchronous belt, also known as a timing belt, is a crucial component in modern manufacturing processes. It plays a vital role in transmitting power and synchronizing the movement of various machinery and equipment. This essay aims to explore the transformative impact of the industrial synchronous belt on manufacturing operations, highlighting its advantages, applications, and potential for improving efficiency and productivity.

Advantages of the Industrial Synchronous Belt:

1.Precise Power Transmission: The industrial synchronous belt operates by meshing with pulleys or sprockets, ensuring accurate power transmission between different machine components. This synchronous power transfer eliminates slippage, providing precise motion control and reducing the risk of damage to equipment.

2.Efficiency Enhancement: Compared to other power transmission mechanisms like chains or gears, synchronous belts offer higher efficiency due to reduced friction and improved mechanical performance. This efficiency enhancement translates into energy savings, reduced maintenance requirements, and enhanced overall productivity in manufacturing processes.

Applications in Manufacturing:

1.Assembly Lines: Industrial synchronous belts find extensive use in assembly line systems, enabling the synchronized movement of multiple components. By maintaining precise timing and coordination, these belts ensure smooth operation, increased throughput, and enhanced production efficiency.

2.Conveyor Systems: Conveyor belts powered by synchronous belts are widely employed in manufacturing facilities for transporting goods and materials. The synchronization provided by the industrial synchronous belt enables seamless and controlled material flow, minimizing jams and optimizing production rates.

3.Robotics and Automation: Synchronous belts are essential in robotic applications, facilitating precise and coordinated movements of robotic arms and actuators. Their accurate power transmission capabilities allow for efficient and reliable operation, enabling robots to perform complex tasks with speed and accuracy.

Improving Efficiency and Productivity:

1.Reduced Downtime: The reliability and durability of industrial synchronous belts contribute to reduced downtime in manufacturing processes. Their low maintenance requirements and resistance to wear and fatigue ensure prolonged operational life, minimizing production interruptions and improving overall efficiency.

2.Enhanced Speed and Precision: Synchronous belts enable high-speed operation while maintaining accurate positioning, making them ideal for applications requiring precise motion control. This characteristic enhances manufacturing speed, accuracy, and consistency, leading to improved product quality and increased productivity.

3.Noise and Vibration Reduction: Synchronous belts are designed to operate with minimal noise and vibration, providing a quieter and more comfortable working environment. This reduction in noise levels can enhance worker productivity and contribute to a safer and healthier workplace.

The industrial synchronous belt has revolutionized manufacturing processes by enabling precise power transmission, enhancing efficiency, and optimizing productivity. Its applications in assembly lines, conveyor systems, and robotics have significantly improved operational performance, leading to increased throughput and enhanced product quality. With the ability to reduce downtime, improve speed and precision, and minimize noise and vibration, the industrial synchronous belt continues to play a pivotal role in modern manufacturing, driving progress and innovation across industries.

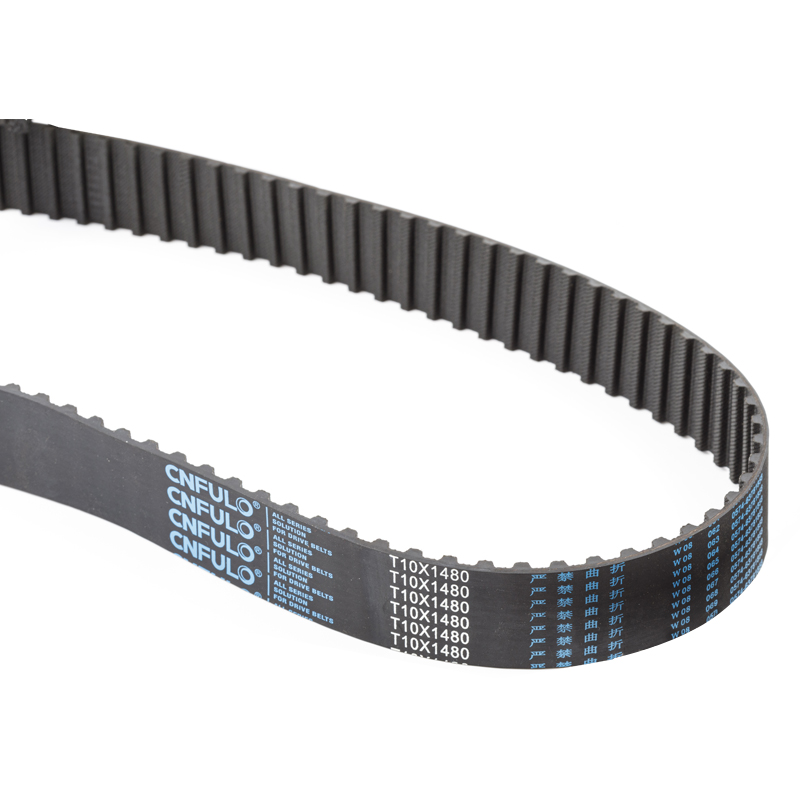

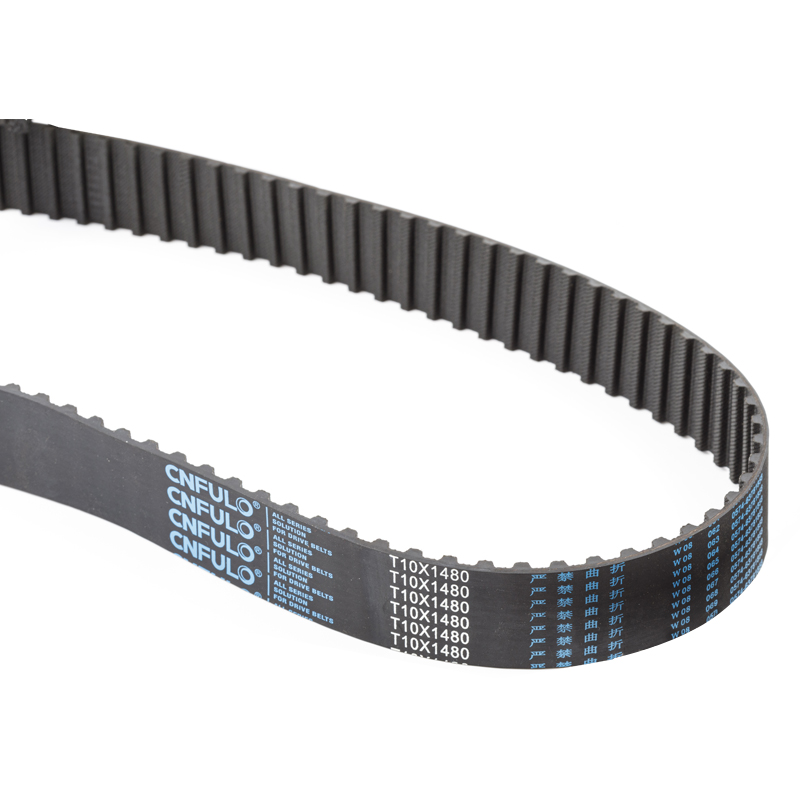

The belt body is made of high-quality synthetic neoprene imported from Japan, hydrogenated nitrile rubber and mixed with various rubber accessories for different purposes; the frame material is high-quality high-strength glass fiber cord imported from Japan; the toothed surface is specially treated with nylon 66 high elasticity Cloth for protection.

Synchronous belt uses belt teeth to mesh with pulley teeth to transmit power, which is a new type of synchronous transmission. Moreover, the product does not require lubrication, no slip, no pollution, and low noise; the transmission efficiency is more than 98%, the speed ratio range can reach 1:10, the allowable linear speed can reach 50m/s, and the transmission rate ranges from hundreds of watts to several Hundred kilowatts, also suitable for multi-shaft transmission.

The product has good dynamic performance and anti-cracking performance, excellent ozone performance, and also has the characteristics of aging resistance, heat resistance, and abrasion resistance.